The Benefits of Virtual Training

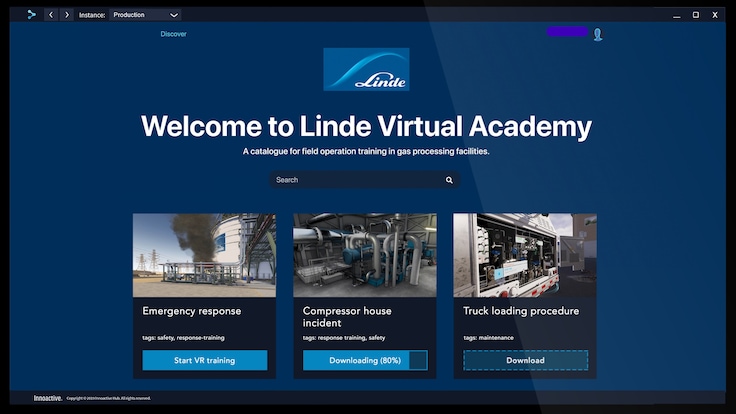

The Linde Virtual Academy from LINDE PLANTSERV® offers plant operators an ideal training tool.

Equipping employees to deal with emergency situations and familiarizing them with routine operating and maintenance procedures … the LINDE PLANTSERV Virtual Academy covers it all. Operators can upskill their staff while also investing directly in the safety and efficiency of their industrial plants.

- Emergency response drills can rarely be practiced under real-world operating conditions. LINDE PLANTSERV Virtual Academy gives oil and gas companies the perfect tool to train for these scenarios.

- Standardized and customized virtual plant environments allow operatives to learn how to respond correctly to critical situations and how to carry out their everyday operation and maintenance tasks more efficiently.

- In addition to efficiency, virtual reality (VR) highlights include the fact that trainees can practice different scenarios from anywhere in the world, minimizing unnecessary travel and resulting carbon emissions.

The smoke is pitch-black, but it has no smell. And although the flames are leaping meters high into the air, they are not raising the surrounding temperature. Even through the fire is only virtual, panic is spreading, especially as the flames move dangerously close to a full gas tank. “Details like the increased heart rate of our virtual reality trainees tell us that their reactions are remarkably similar to the responses you would expect in a real-life situation,” says Feras Alhothali, Innovation Manager with LINDE PLANTSERV. And that is precisely the goal of VR training. The deceptively realistic virtual experiences prepare employees in gas processing plants as effectively as possible for critical and emergency situations. Alhothali has been a VR enthusiast for many years. Linde was an early developer of VR training modules to improve safety and efficiency in oil and gas processing plants.

A World of – Virtual – Benefits

“Thanks to VR, we can bring immersive online learning experiences to trainees in real time – no matter how far away they are. Given that oil and gas plants are situated at very remote locations, this is a huge benefit for plant operators,” points out Philipp von Breitenbuch, Product Manager with LINDE PLANTSERV. He continues: “The fact that we identified the remote and virtual learning trend early on and had mature solutions in place well before the coronavirus pandemic is a tribute to our forward thinking.” As a result of travel restrictions and social distancing regulations, many companies and training providers have had to act quickly to come up with alternatives to in-person, classroom-based learning. No easy task, as Linde expert Alhothali is aware – but he has some words of encouragement: “Once the technical hurdles have been overcome, VR presents a range of compelling benefits. For one thing, courses become globally accessible and are no longer bound to a physical plant.” VR also eliminates unnecessary travel, which saves costs and carbon emissions.

Virtual Training: Primed for Real-Life Hazards

Through customized Virtual Academy training modules, LINDE PLANTSERV has created an efficient vehicle to share expert insights with its plant customers. Alongside tailored solutions, the Academy also offers a steadily growing library of standardized VR training scenarios which can be accessed based on a subscription model. The importance of providing the best possible training to plant employees was illustrated by a study conducted by Salford University in 2017, which showed that, on average, 70 percent of all accidents can be attributed to human error. “Tailored training modules and proactive skill building is the most effective strategy to mitigate the risk of failures and safety incidents,” claims von Breitenbuch. “Training is all the more important when you consider that particularly critical scenarios like accidents involving a major fire cannot actually be simulated in real life for training purposes,” adds Alhothali. How would personnel react, for example, if a fire breaks out in the machine hall or a massive stream of gas suddenly escapes from a plant component? To practice the appropriate responses, PLANTSERV experts have designed bespoke training modules for one of its customers. The customized platform hosts an optimized 3D model of the entire plant and 40 VR training scenarios. “This allows a large workforce to be trained remotely,” says Alhothali. Responding to unexpected incidents in a safe yet realistic environment helps plant personnel to learn from mistakes without having to worry about safety or fire risks, unwelcome costs and possibly plant downtime.

“Tailored training modules and proactive skill building is the most effective strategy to mitigate the risk of failures and safety incidents.”

Up to Speed Before the Plant Has Even Been Constructed

Studies confirm that VR training using simulations is a highly effective approach. It is 15 times more effective than traditional classroom training thanks to the interactive, realistic learning environment. Just like flight simulators have been used for decades to train pilots and prepare them for critical situations, the LINDE PLANTSERV Virtual Academy is bringing the same benefits of simulation to the oil and gas industry. “Even before a new plant goes on stream, the operating staff can familiarize themselves with their new workplace and build the capabilities they will require on the job,” continues von Breitenbuch. “Like a large, constantly growing library, our VR modules are dedicated to individual safety-critical processes and workflows.” As well as training for high-risk scenarios, users can also practice regular field operation procedures and execute maintenance interventions. Another advantage of the Linde Virtual Academy is ease of deployment. Since it is modeled like a common media streaming platform, the only equipment users will need is a VR headset and a laptop. In just a few steps, users have instant, on-demand access to all modules covered by their subscription model. The plant operators can then train their staff when it suits them – at any time and place. Another option allows several operators to work on the same modules in parallel. A continuous feedback loop allows participants to track their progress and see which modules they have successfully completed.

Best Practice Sharing to Benefit the Entire Industry

The Linde Virtual Academy reflects the vast experience Linde has gained by engineering over 4,000 industrial plants for clients around the world and operating over 1,000 of its own plants. Consequently, the simulated plant environments cover up to 95 percent of all plant scenarios in real life. This makes it easier for participants to apply lessons learned to their own plant. The Linde Virtual Academy also serves as a valuable knowledge base. It channels insights gained by customers from live operations into new and expanded modules. This interactive content development process enables oil and gas companies to share their particular experience and lessons learned – for instance, in managing and responding to hazards – with the rest of the industry. “Ultimately, all oil and gas companies have a common interest in raising safety standards across the industry, and Linde Virtual Academy speaks to that willingness to share information,” von Breitenbuch explains.

“Even before a new plant goes on stream, operatives can familiarize themselves with their new workplace and build the capabilities they will require on the job.”

Bundling Knowledge for Next-Generation Talent

Demographic change is set to present plant operators – especially those in Western countries – with an additional challenge over the next five to seven years. It is estimated that around 50 percent of experienced employees will retire from their current jobs around this time. It is assumed that only 50 percent of these retirees will be replaced. “Which means a smaller, inexperienced workforce will be challenged to compensate for the gradual brain drain,” says Alhothali. “Knowledge and experience are essential – not just for operational efficiency, but also for the mitigation of safety risks on a day-to-day basis. LINDE PLANTSERV experts are also committed to closing the talent and skill gaps we can expect to see over the coming years.” Already deployed across Africa, Europe and North America, this technology is increasingly resonating among customers – as demonstrated by a growing number of reference projects. For example, Linde Engineering is setting up a VR training center for a remote, world-class ethylene cracker plant currently under construction. This will allow the customer to get its 100-plus operators up to speed before the remote plant even comes on stream.

Take VR for a Test Drive with New Linde App

In summary, VR technology has the potential to reach beyond the safety benefits outlined above to also transform training programs, reduce learning times and increase effectiveness. We developed the LVA Express app to bring these benefits to a wider audience – quickly and easily. Take the Linde Virtual Academy for a test drive yourself – with the LVA Express app – and explore the potential of VR for your company.