Our broad CO2 plant portfolio is geared towards ensuring the perfect fit for individual application requirements.

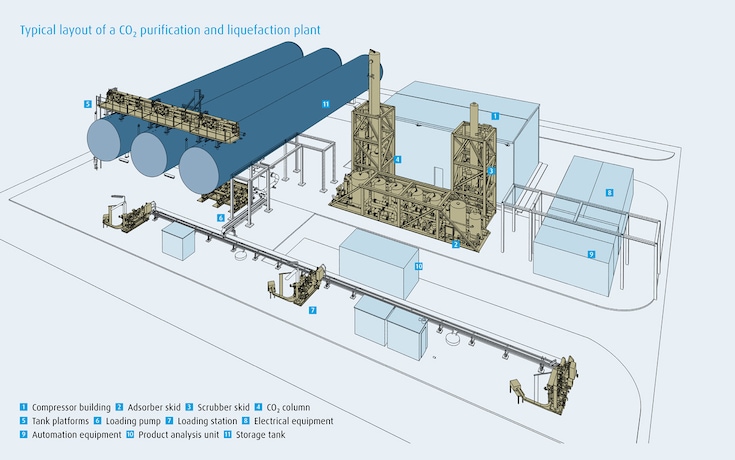

Many customers considering investing in a CO2 purification and liquefaction plant face cost and time pressures. At the same time, they are keen to minimize risks without compromizing on quality. Our portfolio of modular CO2 purification and liquefaction plants is the ideal way to tick all of these boxes.

Our modular portfolio is designed to leverage the benefits of modularization, which include independent off-site fabrication, preassembly and pre-commissioning. Not only does modularization maximize cost efficiencies and quality, it also reduces risks as well as on-site installation time and effort.

All our prefabricated skids – containing equipment, piping, valves, instrumentation, paint, insulation and cabling connected to the skid’s own remote I/O box – are preassembled and completely tested prior to delivery. In fact, our preassembly and pretesting concept has reduced installation effort, commissioning expense and on-site risks by up to 90%. In addition, a compact layout minimizes your space requirements and enables a relocation of your entire plant.

Our modularized units typically support capacities between 100 and 360 metric tonnes per day with a single train.

As shown in the picture, we supply a number of highly modularized skids to include piping, valves, transmitters, cabling, cable trays and a remote I/O box.

| Customer: | BOC |

| Capacity: | 100 t/d liquid CO2 |

| Purity: | 99.99% CO2 (food grade) |

| Scope of work: | Turnkey plant |

| Start-up: | 2017 |

| Customer: | Linde Gas Mexico |

| Capacity: | 200 t/d liquid CO2 |

| Purity: | 99.99% CO2 (food grade) |

| Scope of work: | Turnkey plant |

| Start-up: | 2022 |

(PDF 2.0 MB)

(PDF 353.0 KB)

Our broad CO2 plant portfolio is geared towards ensuring the perfect fit for individual application requirements.

Flexible solutions to improve your carbon footprint.

Meeting individual capacity, purity and flexibility needs through cost-effective, customized designs.

Improving the carbon footprint of fossil power stations and the chemical industry through carbon capture and storage technologies.

Helping customers meet their carbon abatement targets through innovative CO2 scrubbing technologies.

Advancing innovative flue gas scrubbing technologies to industrial maturity in collaboration with strategic partners.

Comprehensive technology portfolio and strategic partnerships advancing oxyfuel combustion to industrial-scale maturity.