Designs Adapted to Your Needs

Our hydrogen (H2) production plants come in many different shapes and sizes to support the highly diverse needs of different industries. Whether you’re using H2 as a reactive gas for a hydrogenation processes, a feedstock for fertilizers, fuels or peroxide products, or as an energy carrier, we have the ideal match for you.

Our comprehensive portfolio extends from conventional H2 through low-carbon (blue) to fully green H2 plants, supporting capacities ranging from 300 Nm3/h to 350,000 Nm3/h and beyond. We also deliver purities all the way up to 99.9999 vol%.

Our hydrogen expertise extends along the full value chain. Click here to dive into the world of hydrogen at Linde.

Our Low-Carbon H2 Offering

Our technologies can capture more than 95% of the carbon generated during the conventional production of H2 to create low-carbon (blue) H2. This is achieved by adding a carbon capture step to conventional processes such as autothermal reforming (ATR), steam methane reforming (SMR) or partial oxidation (POX). You will find more details on Carbon Capture here.

The illustration to the bottom shows how an autothermal reformer uses oxygen (O2) from an air separation unit (ASU) to generate low-carbon H2. After the carbon monoxide (CO) shift conversion, the hydrogen is purified in a pressure-swing adsorption (PSA) unit and then compressed. To enable storage and transportation of large quantities, the hydrogen can also be converted from its gaseous form to liquid hydrogen (LH2). With more than 40 years of experience in the engineering and delivery of H2 liquefaction systems, Linde is the world leader for liquid H2 generation and supply.

The carbon dioxide (CO2) generated during the process is captured from the tail gas of the H2 purification unit by our HISORP® CC technology, by a physical wash system or by a chemical wash system. These technologies can achieve carbon capture rates of up to 99%. The CO2 is then further purified and exported or stored in gaseous, liquid or supercritical phase depending on the requirements of the downstream infrastructure and applications.

Our Renewable H2 Offering

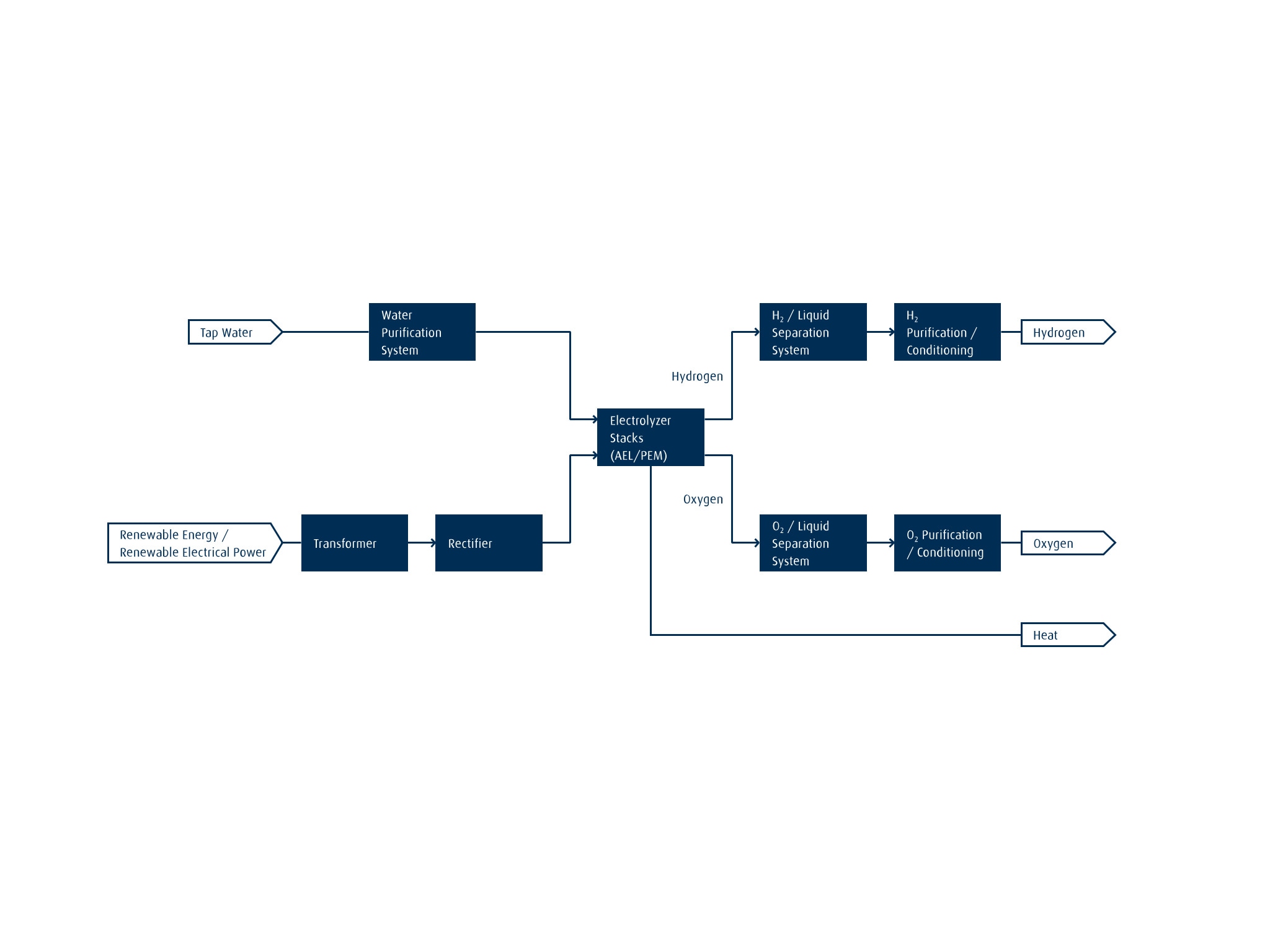

Hydrogen can also be produced by means of electrolysis. If electricity from renewable energy sources is used to split the water into H2 and O2, the resulting H2 is green. The most common electrolyzer technologies used today are alkaline electrolyzers and polymer-electrolyte membrane (PEM) electrolyzers. We currently operate over 80 electrolyzer plants, with more than 375 MW of capacity additionally under execution. Projects span both PEM and alkaline technologies from different original equipment manufacturers.

The illustration on the bottom shows how green H2 could be produced using a PEM electrolyzer. Purified water and renewable power are supplied to the electrolyzer module, which can contain several separate electrolyzer stacks. The water is electrochemically split into H2 and O2. The resulting H2 is then dried and purified.

Looking beyond electrolysis, green H2 can also be produced by means of a conventional SMR or POX process. For this, a renewable feedstock such as biomass or biogas must be used. The overall process is then considered carbon-neutral

Our Conventional H2 Offering

Conventional H2 can be produced from all kinds of hydrocarbon feedstocks via SMR or POX. It can also be obtained by the conversion of CO, followed by a PSA (purification) process or by the recovery and purification of refinery purge gases.

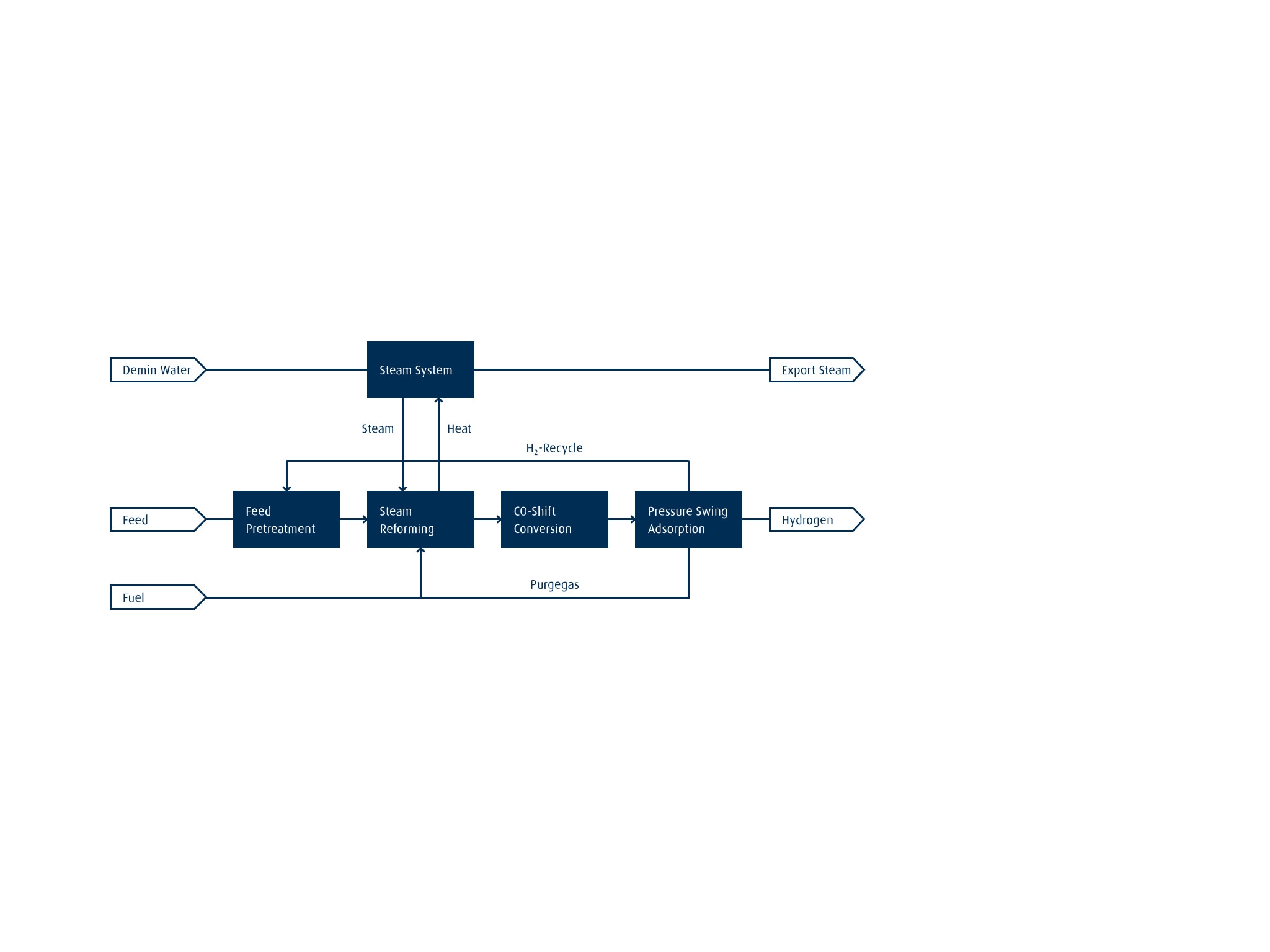

The most common production method is SMR. The illustration to the right shows a typical Linde design for a high-capacity H2 plant. With this process flow, the feedstock is desulfurized and fed into the steam reformer. This is followed by a CO shift conversion. The H2 is purified by means of PSA.

Heat is recovered from both the reformed syngas and the combustion flue gas and this is used to produce process and export steam.