Linde Engineering Dresden

Linde Engineering Dresden offers services covering every step of the project lifecycle – from feasibility study to commissioning and start-up.

Engineering Expertise

We employ hundreds of skilled engineers and specialists, deploying state-of-the-art tools and systems to maximize efficiency. As integral part of Linde Engineering, we benefit from access to fully equipped research and development (R&D) centers, including extensive lab and pilot plant facilities. This, combined with our technology-focused heritage and full EPC competence, enables us to scale up new processes from the lab through pilot plants to full commercial-grade units.

Our Portfolio Covers a Wide Variety of Industries and Process Plants.

Hydrogen

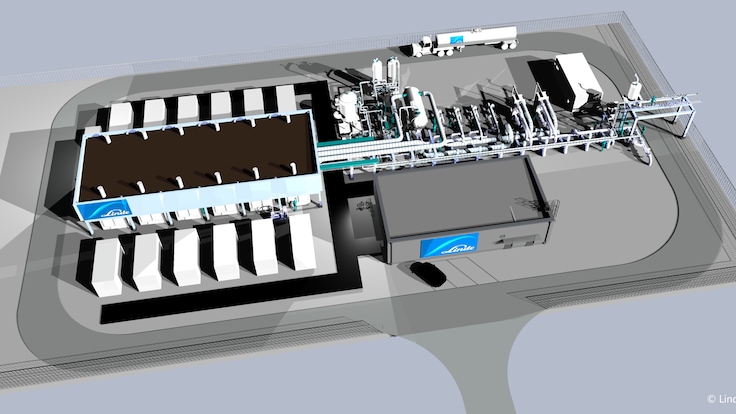

Linde is a global leader in the production, processing, storage and distribution of hydrogen and electrolysis plants worldwide. By combining our CO2 and hydrogen expertise, Linde Engineering Dresden can provide solutions for blue hydrogen applications.

CO2 Plants

Concerns over global warming and climate change are leading to intensified global efforts to reduce the concentration of greenhouse gases such as carbon dioxide (CO2) in our atmosphere.

Across industries, there is a growing focus on the need to remove CO2 from flue gases released, and to purify and liquefy the CO2 for alternative usage. Linde Engineering in Dresden considers carbon capture to be a key strategic element in meeting current and future CO2 emission reduction targets.

Polyolefin Plants

Polyethylene (PE) and polypropylene (PP) polymers are experiencing the highest demand and growth rates worldwide. More than 50 percent of all ethylene produced is used by polymerization processes for the production of PE and PP. Building on partnerships with Univation Technologies, LLC and W.R. Grace that date back more than 40 years until this day, Linde has gained a profound knowledge base in both engineering and project execution for such plants.

Air Separation Plants

As one of the largest and most experienced suppliers of air separation plants and industrial gases worldwide, Linde delivered over 4,000 air separation plants around the globe. Building on our long-standing experience in both plant engineering and operation, Linde Engineering Dresden supplies modular- and containerized air separation units throughout the EMEA region.

Pilot and Special Plants

To advance commercialization of new and promising technologies, we also design pilot plants at the sites of our industrial partners. These are often integrated into commercial process plants, enabling us to test new technologies under realistic conditions and bring the latest engineering innovations to our customers as quickly as possible.

Our world-renowned engineering expertise, innovative strength and process know-how enable us to reduce the risk and complexity of special projects. We guide our clients through the entire project lifecycle. Building on our long-standing experience in the design of special plants, we offer prefabricated solutions to accelerate the implementation timeline, minimize construction effort and maximize cost efficiencies for our customers.

Complex Plant Revamps

Customers all over the world rely on us to handle challenging and time-critical revamp projects of complex plants, and to find the best solutions for their needs. We integrate revamp technologies into existing plant designs, rerate equipment and existing installations, modernize process control and safety systems and ensure compliance with all applicable regulations.