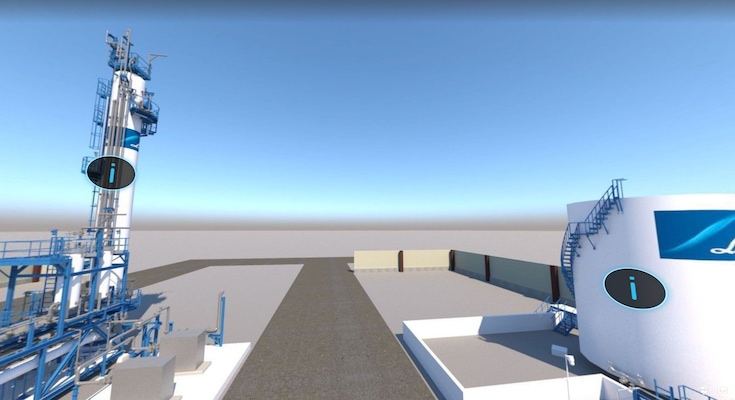

Pre-engineered solutions tailored to individual requirements, offering the full range of liquefaction technologies, including its most recent standardized LNG plant concept StarLNG®.

Pre-engineered solutions tailored to individual requirements, offering the full range of liquefaction technologies, including its most recent standardized LNG plant concept StarLNG®.

Linde has the know-how and experience to individually design and build highly efficient base load plants for even the largest world-scale LNG plants.

Tailored solutions for the recovery and liquefaction of valuable helium gas from natural gas.

Offering nitrogen rejection units with tailored process technology to ensure highest efficiency and economics.

Long-standing experience in the design, development and construction of plants to recover NGL and LPG.

Linde has extended its StarLNG® product portfolio to optimally serve the evolving BioLNG market.

Linde is one of the world’s few technology contractors to cover the full T-EPC project spectrum for ethylene plants, and has already successfully delivered over 60 plants.

Positioned at the heart of ethylene plants, Linde’s steam cracking furnaces play a crucial role in the manufacture of many base products while also defining the yield, efficiency and profitability of olefin plants.

Electrification project for steam cracking furnaces has the potential to cut CO2 emissions by 95 percent or even more.

Linde supports its customers in the petrochemical industry on their journey towards greater sustainability.

Linde’s EDHOX™ catalytic on-purpose technology builds on the oxidative dehydrogenation of ethane to create an innovative, low-emissions path to ethylene and acetic acid.

Through its collaboration with ENEOS and BASF, Linde offers highly efficient, mixed-solvent butadiene extraction processes for excellent 1,3 butadiene yields and product purities plus outstanding process performance.

Linde has a long history in the production and supply of acetylene gas.

Linde offers a thermal HydroDeAlkylation (HDA) process for the production of benzene from refinery and petrochemical streams.

Optimizing furnace operational efficiency in real-time

Linde is a one-stop provider of polyethylene plant services spanning everything from design and construction to smooth integration in petrochemical complexes together with steam crackers and other downstream units.

Supporting environmental regulatory compliance, Linde provides one stop WAO solutions spanning state-of-the-art design, engineering and supply of prefabricated skids for treatment of spent caustic.

Linde has long been supplying thermal oxidation and incineration systems to petrochemical customers across the globe, bringing an unmatched skillset to today's complex hazardous waste disposal challenges.

Linde has decades of experience in designing and building fired heaters and special crackers tailored to the petrochemical industry, including ethylene-dichloride (EDC) cracking furnaces.

Based on our world-leading technologies, our experts have already delivered over 1,000 CWHEs tailored to the exact heat transfer needs.

As a global leader in the field of plate-fin heat exchanger technology and vacuum brazing, we have supplied over 12,000 units since 1981.

World expert in cryogenic process plant design, we are a technology leader in the engineering of packaged units, coldboxes and columns.

Discover our vast range of robust, reliable solutions with capacity ranges from around 500 Nm3/h to 195,000 Nm3/h.

Cryostar provides a wide range of equipment for the process industry including pumps, turbines, compressors, vaporizers, heat exchangers and filling stations.

Discover our broad range of standardized and customized cryogenic tanks designed for the most demanding applications.

Delivering helium storage tanks and UN portable tanks (HELICS™) to the highest safety and efficiency standards for all applications.

The use of electricity for heating – ideally from renewable sources – has the potential to massively reduce CO2 emissions.

Introducing the carbon management toolbox for petrochemical plants.

How to slash cracking furnace emissions by 95%!